When it comes to curved steel finding the precise measurements is a challenging undertaking.

Sheet metal bend radius calculator mm.

To solve this cmrp provides easy to use measurement calculators.

20 gauge 0 040 1 01 mm 0 2 5 08mm.

Most sheet metal materials.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

Cells on the right will output the desired values.

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

Sheet metal calculator bend allowance equations and calculator.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length.

Sheet metal bend allowance calculator determines the bend allowance amount of metal to be added to the total layout when forming sheet metal.

Let s start with 90 degrees bend which is the most simple scenario.

The tool can calculate the required bending force for bending aluminum stainless steel mild steel and weldox or strenx high strength steels.

As this happens you gain a small amount of total length in your part.

The bend allowance added to the flange lengths is equal to the total flat length of the part.

60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them.

Therefore the bend allowance added to the flange lengths is equal to the total flat.

Most sheet metal materials will conform to the calculations.

Discover all our calculation tools in the calculators section of the top menu.

This tool allows you to determine tonnage internal radius v die opening and minimum flange you just have to insert the characteristics of the sheet metal to be bent.

This page also includes a link to a on line sheet metal bend allowance calculator.

The bending tool has a radius of 30 mm which means that our inside bend radius r is 30 mm.

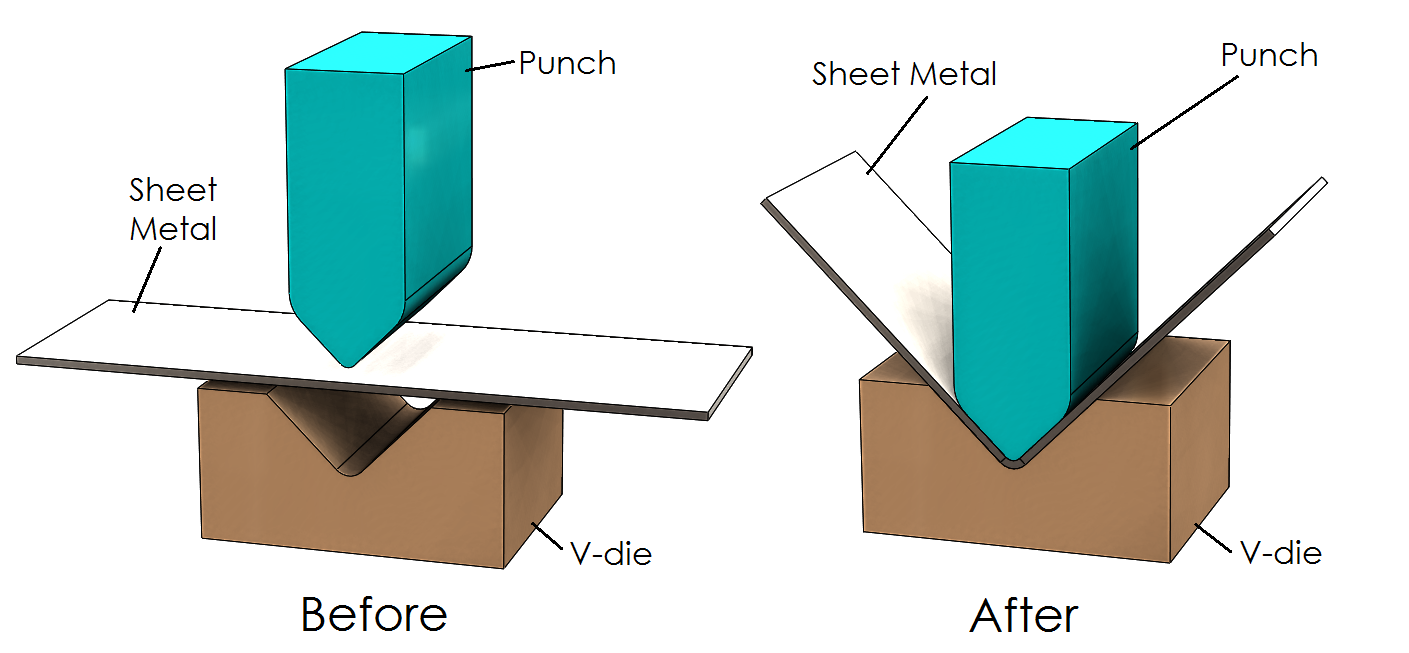

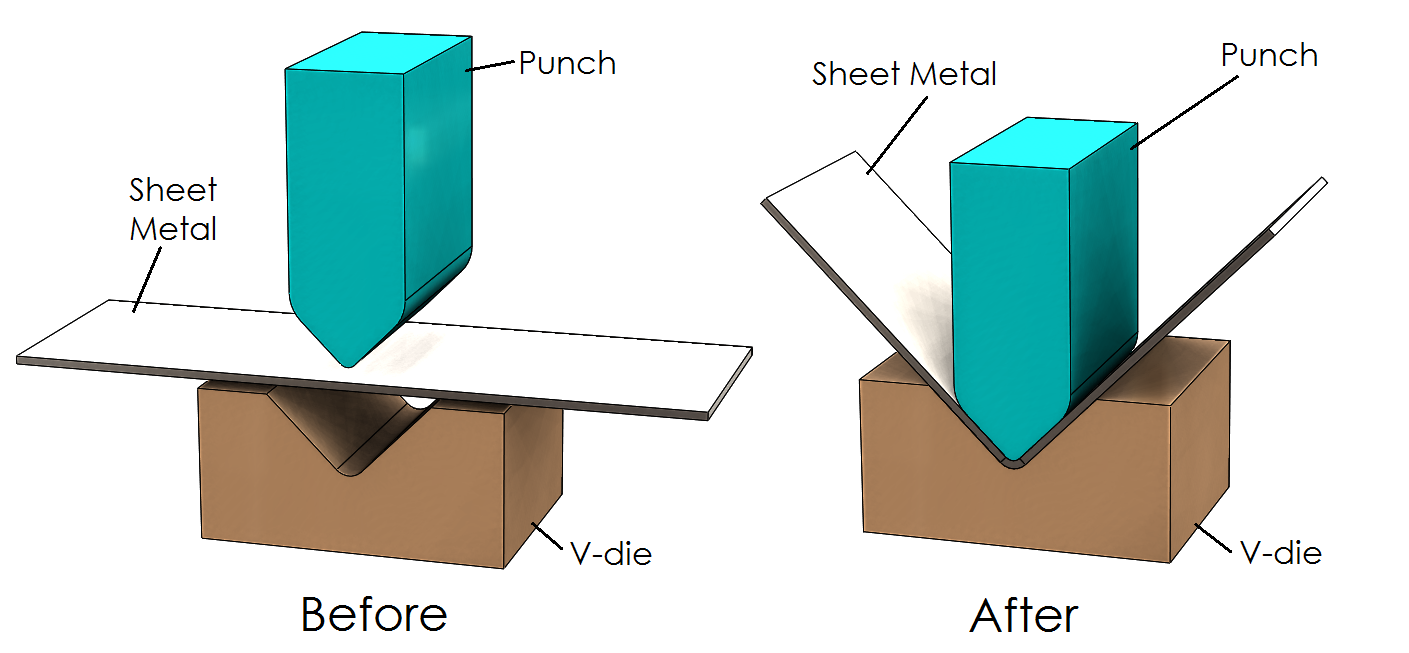

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

20 gauge 0 040 1 01 mm.

The bend deduction sometimes called the bend compensation describes how much the outside of the sheet has been stretched.

The bend allowance describes the length of the neutral axis between the bend lines or in other words the arc length of the bend.

The following illustration shows the equation calculation for determining the bend allowance when forming sheet metal.

Inside bend radius r inches must be greater than 90 and less than 180 degrees.

Bend allowance sheet metal change inlength due to bending operation calculator.