Once dimension x increases in the joggled formed in the sheet metal above the maximum shown in the table we have to put the 2 bends into the sheet separately.

Sheet metal joggle dimensions.

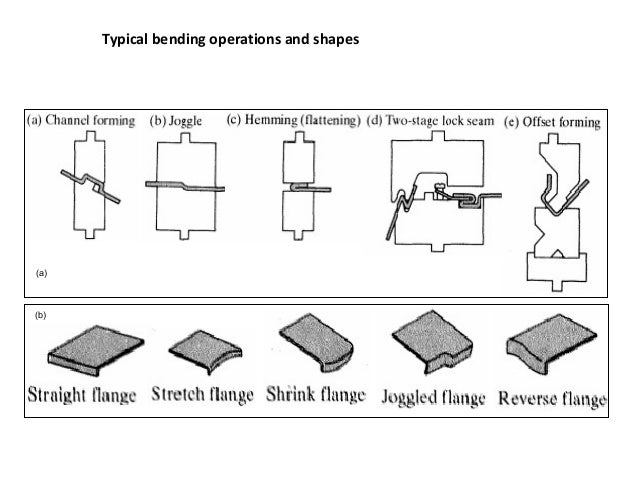

A joggle bend in sheet metal and a joggling tool joggling 5 also known as joggle bending is an offset bending process in which the two opposite bends are each less than 90 see following section for how bend angle is measured and are separated by a neutral web so that the offset in the usual case where the opposite bends are equal in.

Previous editions covered economic order quantity in batch production and the accuracy of things made from rolled sheet stock.

For sheet metal work over 140mm long please see our cnc z bend table.

I have attached a pdf of a part i m working on in inventor.

Columnist gerald davis continues a discussion of 3 d cad and precision sheet metal manufacturing in part iii of a four part series focusing on design guidelines for sheet metal.

I appreciate any suggestions etc.

Remove the part from the brake and check the joggle for correct dimensions and clearance.

Next month concludes with the pros and cons of hems jogs and forming tools.

A joggle is an offset formed to provide for an overlap of a sheet or angle which is projecting in the same plane.

Bend the part up until the correct height of the joggle is attained.

This then becomes an operation for one of our cnc press brakes.

Release the brake and remove the part.

Item 168753 model 11786.

I am needing the joggled area to be vertical as it s shown on the pdf.

I tried using the flange but it follows the bend line.

Turn the part over and clamp it in the brake at the second bend line.

Hillman 12 in x 24 in cold rolled steel expanded sheet metal.

1 all manufacturing tolerances used up to that point such as laser cutting tolerances welding tolerances and more 2 all bend tolerances for the entire part added together we call this an uncontrolled dimensions because there are additional tolerances to consider.