I would overlap the panels butt welding floor pans is not much fun unless you have completely flat floors.

Tig welding floor pans.

Silcon bronze for body work and floor pan.

5 posts page 1 of 1.

A smaller tungsten rod and 100 argon shielding gas will give the best chance for a perfect weld.

Many years ago i used a miller dc itevrner gold seal 140 to weld cans together.

Firing up the miller spot welding to make sure the floor pan stays put.

Welding basics how to tig weld livestream part 1 of 2 eastwood duration.

Fery february 13th 2016.

Back then welding cans together was a challenge for even an experienced welder but today s itevrners with balance control freq settings and arc stability at low amps means its an easy task.

Then strip to bare metal on both panels anywhere they contact each other.

We show how to install a reporduction floor pan patch using the national parts depot floor pans for the 1972 f100.

Another option is using panel adhesive to put the floors in along with some plug welds to be extra sure.

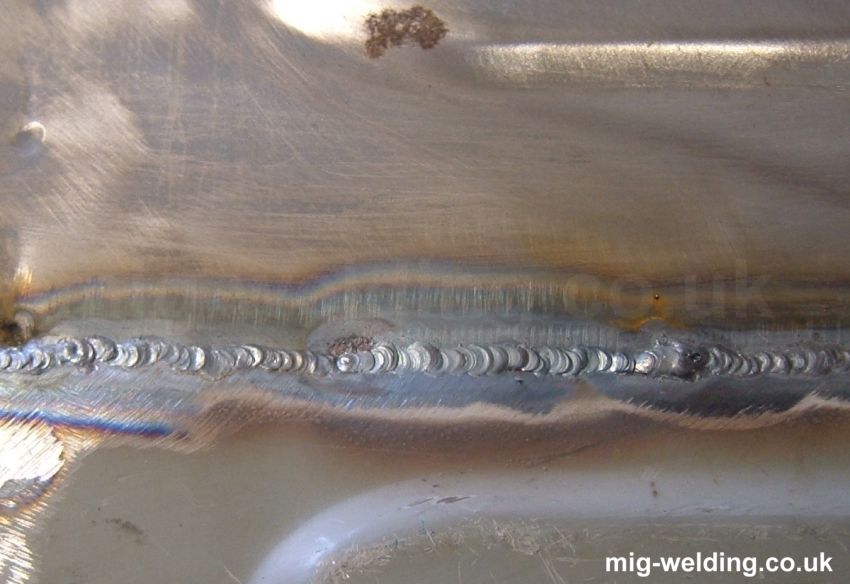

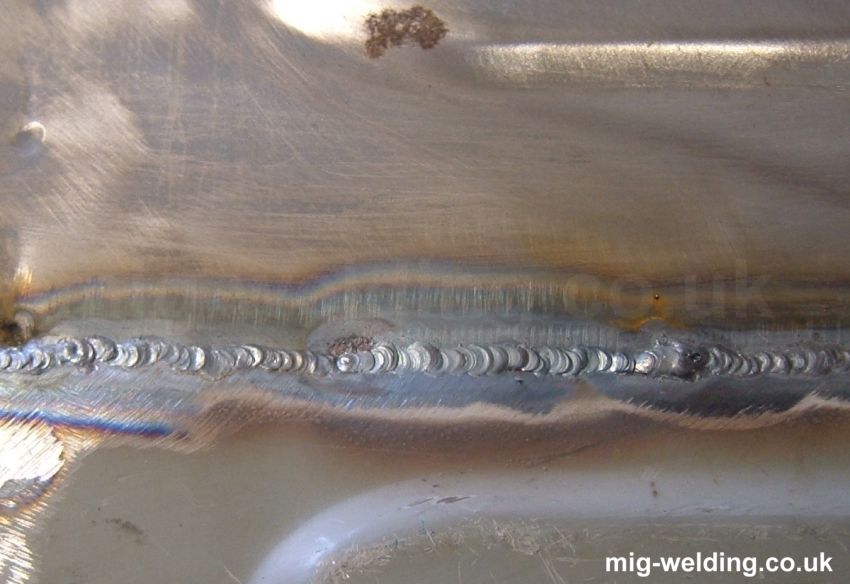

The sheet metal used in constructing floor pans is a thin gauge that can be burned through rapidly.

Using weld through primer will help with rust issues between the panels.

If you don t have experience tig welding sheet metal you can expect to burn through the floor pan sheet metal in several places.

You can weld in panels by over lapping and plug welding them but this method is prone to trapping moisture between the panels.

The method most often used seems to be the mig welding process.

The best way to do the over lap style repair though is make shure you have good metal to weld to on the original panel.

Tig welding tips questions equipment applications instructions techniques tig welding machines troubleshooting tig welding process.

Benefits of tig.

Heat control setting vary between welding machines so doing a practice run on some of the metal that was cut out of the floor pan area would be a wise idea.

Mark mcdonald and aaron ellenbaum of detroit speed engineering explain why they prefer to tig weld body panels using dynasty tig welders.

Electrode positive only and using scratch start.